How are amputation alloy heads produced?

As the most important part of the gear, the quality of alloy head directly determines the efficiency and effectiveness of mining. Most of the alloy head manufacturers in the market are outsourced or customised, which makes it difficult to control the quality of the alloy head.

In order to ensure the quality, the first line of gear brand manufacturers are generally configured with their own alloy production line, so that whether in the alloy formula or model can be independently controlled to ensure that each parameter of the high standard and quality stability, Xinda gear has its own alloy production line to ensure the quality of the alloy.

So, how is the alloy head produced? Today we will unveil the mysterious veil of the alloy head production line for you, and explore the mystery of manufacturing alloy head for cut-off gears together.

The first step: mixture preparation

Mix preparation bin

The brand alloy of the first line of trunnion all adopts imported tungsten carbide raw materials, whose components are mainly tungsten carbide, cobalt powder and other trace elements.

In order to keep the alloy head of the cut-off tooth with both hardness and strength, extra care should be taken on the formula, especially the proportion of tungsten and cobalt as well as the moulding agent, all of which should be able to be customized for the alloy formula with different requirements according to the different rock properties. Cinda Gear has 100,000 pieces of rock data, and has already achieved the customised production of alloy.

Basic raw materials of tungsten-cobalt alloy

Step 2: Press moulding

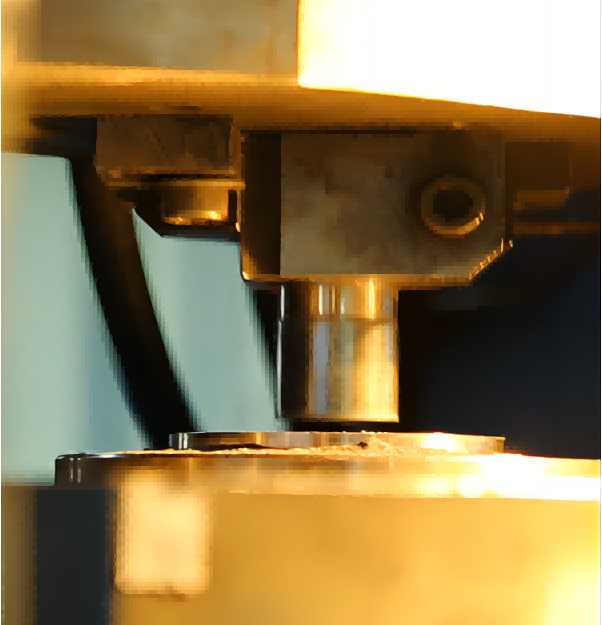

Alloy press workshop

After mixing, the alloy material will be put into the press mould to be pressed into shape.

In order to improve the cutting efficiency of the cut-off teeth, Cinda has made special treatment on the design of the alloy head, which is designed as a prismatic shape, making the tip of the alloy head more sharp.

In fact, most manufacturers in the market do not dare to design in this way, because when encountering hard rock, the sharper it is, the easier it is to break, which greatly tests the quality of the alloy.

Alloy press moulding

Step 4: Alloy Sintering

After forming, the alloy head still needs to go through the sintering process. The sintering process through the pressure sintering furnace can effectively reduce the alloy porosity, so that the organisational structure of the cemented carbide is more dense, which can also improve the various physical and mechanical performance indexes of the cemented carbide.

In addition, at high temperature, the forming agent pyrolysis, so that the powder particles combined with each other to form a solid whole, tungsten carbide and cobalt chemical reaction between the formation of the special structure of the cemented carbide, so that the alloy head perfectly achieve the best balance of hardness and bending strength.

Sintering workshop

Step 4: Surface treatment

High-temperature sintered cemented carbide parts usually also need to be finish-machined to achieve higher precision and surface quality.

This step is mainly to improve the surface accuracy of the alloy. The precision error of Xinda's truncated alloy head is about one-tenth of a hair's breadth, which perfectly circumvents the problem of the alloy head falling off from the tooth body.

Gear head after surface treatment

Step 5: Assembly of the cut-off teeth

Assembling and moulding of cut-off teeth

At this step, the alloy head can be assembled in the production line, through a series of processes, such as welding, to become a high-quality interceptor teeth, which are sent to the major mines and engineering tunnels.

It can be said that every link in the process of alloy head of the gear cutting requires precise operation and parameter control to ensure the quality and performance of the final product. This is also the reason why Xinda Gear can quickly become one of the top brands in China and favoured by many customers.

PRODUCTS

Zhuzhou Xinda Machinery Technology Co.,Ltd.

Contact:Vivian

Tel:+86-731-22888117

Mobile/WhatsApp:+86 15292172314

EMail:xinda@xdcuttingpicks.com

Zhuzhou Xinda Machinery Technology Co Ltd ©All Rights Reserved.